Skip to content

Enamellings – properties from A to Z

- Adaptability

High quality enamel is available for every need. Taking into account the design requirements, enamelling can be adapted to any task.

- Printable

Enamel coatings can be printed in multiple colours using screen printing or decals. After a subsequent stoving process, the images created in this way are permanently preserved. The colour brilliance of printed enamel is impressive.

- Resistant to chemicals

Enamellings are resistant to aggressive chemical substances.

- Electrically neutral

The composite material enamel-metal never loses its isolating properties. Enamelling always remains electrically neutral.

- Colourful, colourfast

Enamellings can be produced in many hundreds of colours and colour gradations. As the colours are fused in during the stoving process, yellowing and greying are impossible. The colours can be glossy or matt.

- Dimensionally stable

The material combination of enamel and metal gives the enamelling a high degree of dimensional stability. The following metals are used for industrially produced enamelling: Steel, cast iron, aluminium, stainless steel.

- Customisable

The creative freedom of engineers and designers is almost unrestricted by enamelling. However, correction after enamelling, e.g. by subsequent bending/folding, is almost impossible. Therefore, close cooperation between the designer and enameller is highly recommended.

- Glass hard and scratch resistant

Thanks to the special surface coating, enamellings are in no way inferior to the abrasion resistance typical for glass. The glass-hard enamel surfaces are therefore very durable.

- Graffiti proof

Enamelled surfaces are paint-repellent. Adhesives and other chemical substances can be removed effortlessly. Hard times are dawning for graffiti on glass-smooth enamel surfaces.

- Skin-friendly

Enamellings are not only good to look at, they also feel good to touch. The closed, non-porous surface of enamelled products is perceived as very pleasant when in direct contact with the skin.

- Hygienic

Various tests have proven that bacteria and other organisms are unable to find a breeding ground on enamel surfaces. The glass-smooth enamel surface is therefore exceptionally hygienic. The so-called “invisible dirt” has no chance of sticking to enamelled surfaces.

- Corrosion resistant

The enameled surfaces are permanently protected against corrosion. In the toothing area of the materials, the enamel-metal fusion layer also prevents any rust infiltration. Contact corrosion due to ion migration or element formation at connection points with non-enamelled metals is also prevented.

- Durable, chip resistant

Enamelled products are extremely durable. The surface can only be destroyed with rough force. The fact that enamel chips off is a verdict that today can only be described as prejudice. Modern thin-film enamelling is very flexible and therefore shock resistant. Enamelled products are therefore extremely durable and have a remarkably long lifespan.

- Lightfast

Enamelled surfaces can be permanently exposed to intense sunlight. Even UV radiation cannot change the colour of enamelled surfaces.

- Material compatible

Enamelled surfaces are highly compatible with other materials. Even in direct contact, e.g. with plastic joint tapes, there is no discolouration.

- More than just a coating

An enamelled surface is formed by applying enamel (a type of glass) to metal. Depending on the type of metal and material thickness, a stoving process at temperatures of up to 900°C results in an interlocking layer between the enamel and the metal. By combining glass and metal, enamelling offers the advantages of both materials. Enamelling combines the strength and elasticity of metal with the hardness and chemical resistance of glass.

- Modifyable

By incorporating ceramic materials, the abrasion resistance, which is a prerequisite for certain technical applications, can be significantly increased. Machine parts that are exposed to heavy mechanical abrasion (abrasive wear) can be specifically protected by such special enamelling.

- Not flammable

Enamel coatings are non-flammable and do not release any toxic vapours even in direct contact with fire. (Building material class A1 according to DIN 4102)

- Easy to clean

The smooth glass enamel surface prevents dirt from sticking. They can simply be wiped away – no polishing required. Enamelled surfaces do not require any special care products. Chemicals used in the household (e.g. nail varnish and its remover, cleaning agents and detergents) cannot harm the enamelled surface.

- Physiologically harmless

Enamelled utensils in which food is stored, prepared or cooked(dishes, pots or pans) do not contain any substances of concern. Enamellings for these applications are therefore physiologically harmless.

- Quality checked

The member companies of the Deutscher Email Verband e.V. produce in accordance with the standards laid down in the manual: “Quality requirements and test specifications for enamellings”.

- Recyclable

Regardless of the base metal used, enamelled products are always recyclable. Enamelled coatings are recyclable and can be melted down without further harming the environment.

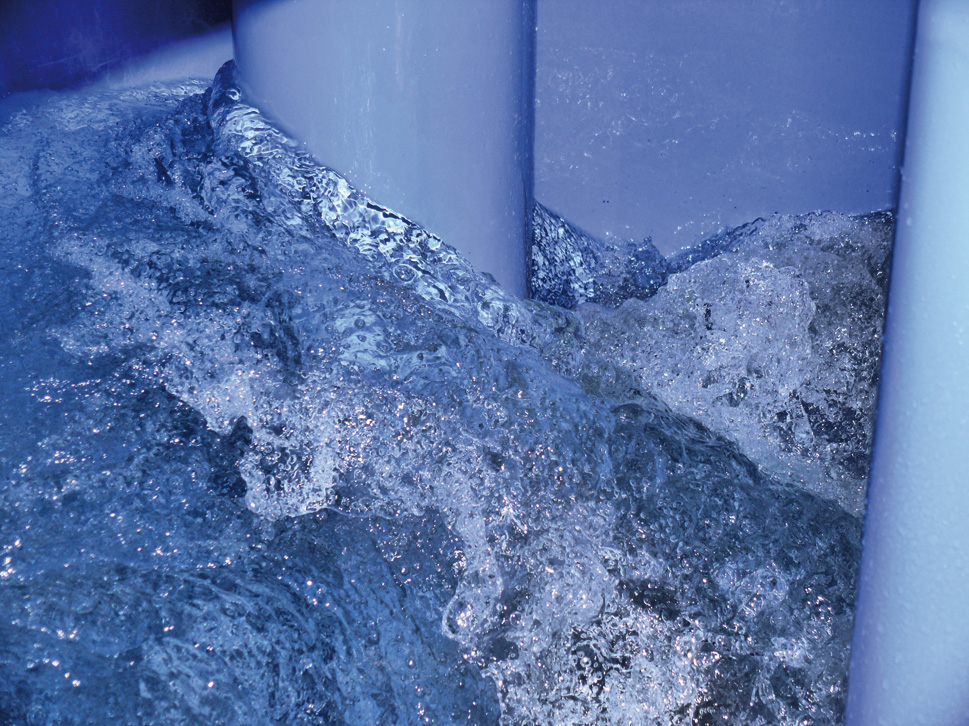

- Acid resistant

Depending on the application, enamellings against acids or alkalis, hot and aggressive water can be produced. Neither properly used cleaning detergents nor “acid rain” can harm enamelled surfaces.

- Impact resistant, hardwearing

Modern enamel coatings have a thin layer structure, because thin layers can withstand more: a glass rod breaks – a glass fibre does not. Today, modern enamelling can only be destroyed by brute force.

- Dirt-repellent

Enamelled surfaces do not become electrostatically charged. In contrast to plastic surfaces, flying dust is not attracted to enamelled surfaces.

- Temperature resistant

Enamelled coatings are resistant in the temperature range from -60 to +450°C. All properties of the surface protection are retained within this temperature range.

- Thermal shock resistant

Extreme temperature changes are no problem for modern enamelling. They can even withstand a thermal shock of 300°C without any damage.

- Environmentally friendly

The raw materials required for enamelling (metals and inorganic silicates) are available in sufficient quantities worldwide, even in the long term. Enamels and the enamel-metal composite are manufactured using environmentally friendly processes. In general, enamellings do not contain any substances that are naturally harmful, such as lead, cadmium or solvents. The only dispersion medium used in the enamelling plant is simply water. This means no burden for employees and no burden on the environment.

- Composite material

The enamel-metal bond is permanently inseparable. At the boundaries between metal and enamel, the two materials are inseparably fused together. The adhesive strength of this bond reaches up to 100N/mm² (adhesive strength in tensile test).

- Producable in a variety of ways

There are almost 20 different application processes in the enamel industry. The choice of the right alternative depends on the shape of the parts to be enamelled and a number of other constraints.

- Reduced maintenance

Enamelled surfaces are largely maintenance-free. Water is usually sufficient for cleaning. Outdoors, enamelled surfaces are kept clean “naturally” by the rain.

- Economical

Only from a superficial point of view are enamellings more expensive than other corrosion protection methods – and that even not in every case. However, enamelling has a remarkably long lifespan. Enamelling not only provides high-quality and ecological surface protection, but also a very economical one. An objective cost-benefit comparison speaks in favour of the use and application of enamel coatings. Despite higher purchase costs in some cases, the cost-effectiveness of enamelled products is unsurpassed in the long term.

- Reliably weather-resistant

Enamellings are neither attacked by the salty North Sea climate nor by the aggressive atmosphere in industrial regions. UV radiation cannot change the colour of enamelled surfaces.